March 1, 2021

LIVONIA, MICH. & STERLING HEIGHTS, MICH. – March 1, 2021 – Effective immediately, Colleen Haley has been appointed Chief Executive Officer of Quality Metalcraft/Experi-Metal Holdings Corporation (QMC-EMI), a provider of innovative stamping and joining assemblies for the automotive, commercial vehicle, aerospace and defense industries. Ms. Haley brings diverse global experience and deep operational expertise to QMC-EMI and will lead the company through its next phase of growth in the mobility market. She previously served as Group Vice President of Operations for Parker Hannifin, a Fortune 250 company and global provider of motion and control technologies.

Ms. Haley commented on the appointment, stating: “I couldn’t be more excited to join QMC-EMI. The company’s highly effective business model and talented team uniquely position it to capitalize on the rapidly evolving automotive industry and help shape the future of mobility. I am looking forward to seizing on opportunities for future growth and innovation, while continuously strengthening our ability to provide customers with the structural solutions they need to get to market faster and with industry-leading products.”

“Colleen’s experience and leadership is a perfect fit for QMC-EMI,” said Peter Grady, Executive Chairman, QMC-EMI. “She will help position the company for accelerated growth and deepen its reputation as a flexible customer partner with end-to-end prototype and niche production capabilities.”

For 30 years Ms. Haley has served in commercial and operational leadership roles in companies across automotive, industrial and off-road vehicle markets. Prior to her tenure at Parker Hannifin, Ms. Haley spent more than 15 years at Yazaki Corporation, a global automotive parts supplier. She rose through the ranks at Yazaki, holding leadership positions including President of several global customer business units and leader of South American operations. Prior to Yazaki, Ms. Haley served on the management team at ALCOA, the world’s eighth largest producer of aluminum.

“We are thrilled to have Colleen at the helm at QMC-EMI,” said Steven E. Karol, Managing Partner and Founder of the Watermill Group, the strategy-driven private investment firm that owns QMC-EMI. “She is a consummate industry veteran who will advance the collaborative strategy of these sister companies, help deepen their unparalleled commitment to service and further embed and operationalize their shared values, as epitomized by their focus on safety and integrity.”

From Michigan State University Ms. Haley has received a Bachelor of Science degree in Psychology and a Master of Science degree in Human Resources and Labor Relations. She is past President and current member of the graduate program’s Alumni Advisory Board.

ABOUT QUALITY METALCRAFT, INC.:

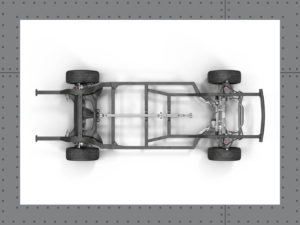

Founded in 1964, Quality Metalcraft, Inc. (QMC) is a premium, niche provider of highly engineered, metal formed assemblies serving a wide range of transportation industries, including automotive, aerospace and defense, heavy trucking and construction equipment. The company specializes in advanced prototyping, in-house tooling, low-to-medium volume production and factory assist services. Headquartered in Livonia, Michigan, QMC is a highly technical organization with an adaptable, flexible manufacturing footprint.

ABOUT EXPERI-METAL, INC.:

Headquartered in Sterling Heights, Michigan, Experi-Metal, Inc. is a leading provider of highly engineered, metal formed prototypes, sub-assemblies, full Body-In-White (BIW) assemblies and bridge production in the automotive, aerospace, defense and alternative energy industries. Since 1959, customers have relied on EMI’s attention to excellence and dedication to continuous improvement.

Media inquiries:

For QMC-EMI

Amanda Backus

734-261-6700

For Watermill Group

Joanna Clark

207-712-1404

Click here for a PDF version of this press release.