January 10, 2023

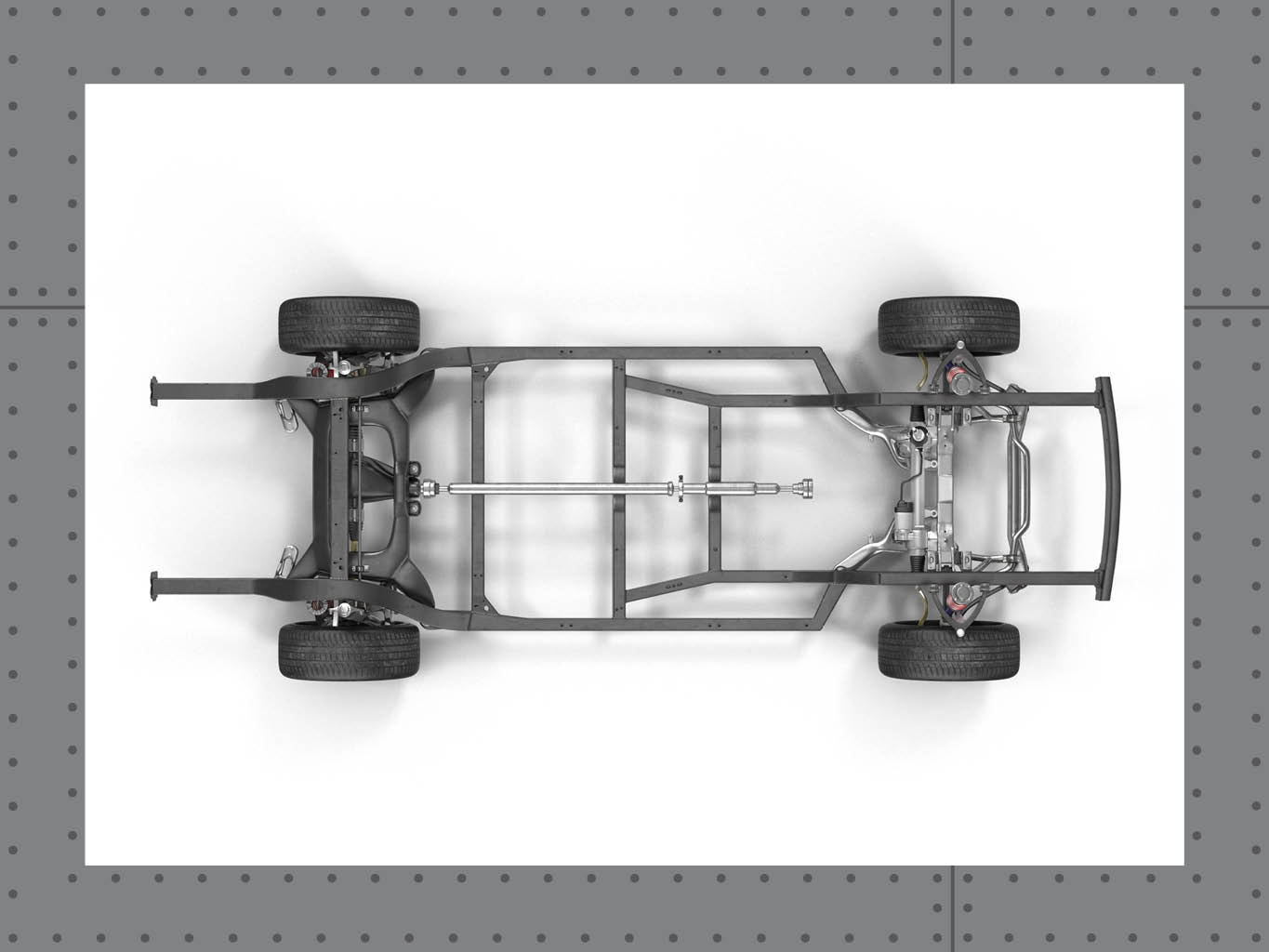

We are a full service sheet metal supplier that specializes in aerospace and automotive welding. Our capabilities and experience span from simple fastener installation to automotive frame welding to full vehicle Body in White (BIW). We build tools, stamp, laser cut, measure, and assemble industry-leading metal frames. Our highly skilled technicians are qualified to AWS standards for GMAW, GTAW, MIG, TIG, and RSW processes. This range of welding technologies means we are ready for your next automotive frame welding program.

We specialize in both manual and robotic automotive welding, allowing us to customize the manufacturing process to give you the repeatability and flexibility you need.

Our welding technologies include:

- AC manual weld guns (RSW)

- DC manual and robotic weld guns with adaptive controls (RSW)

- Press welder for fasteners (RSW)

- Manual and robotic welders (MIG)

- Fronius “cold metal transfer” manual and robotic welders (CMT)

- Manual welding equipment (TIG)

- Laser welding

- Drawn arc stud welding

Laser Welding

Our laser welder allows us to better assist you with programs requiring exotic welding, providing accurate, superior strength finishes. Laser welding is ideal for welding hard to reach areas, enabling precision and quality in previously inaccessible areas.

Manual Welding

Manual welding, a traditional process, is a lower cost alternative for low volume projects and assembly tooling. It requires less programming and a shorter start-up time, instead relying on the decades of experience and quality assurance of our experienced craftsmen.

Robotic Welding

Robotic welding is the newer, technology based approach for welding programs that require high repeatability, such as a BIW build up. There are many benefits of robotic welding, including:

- Reduced piece price over the life of the project

- Increased quality and repeatability in higher volume programs

- Increased rate and flow

In addition, we are able to test the repetitive dimensional quality of your program through a coordinate measuring machine (CMM) or scanning, ensuring repeatability is met. We also have automated weld tip dressing on all robotic cells, which allows us to reshape weld tips to meet specifications ensuring quality throughout the program.

Each of our three Centers of Excellence utilizes state-of-the-art equipment with capabilities for all of your advanced joining needs, making us a leader in automotive frame welding. From simple fastener installation to full vehicle BIW builds, our customers benefit from our rapid response, manual-driven processes, production intent, and robotically executed precision joining.

#qmcemi #automotivewelding #framewelding #sheetmetal #laserwelding #exoticmetals