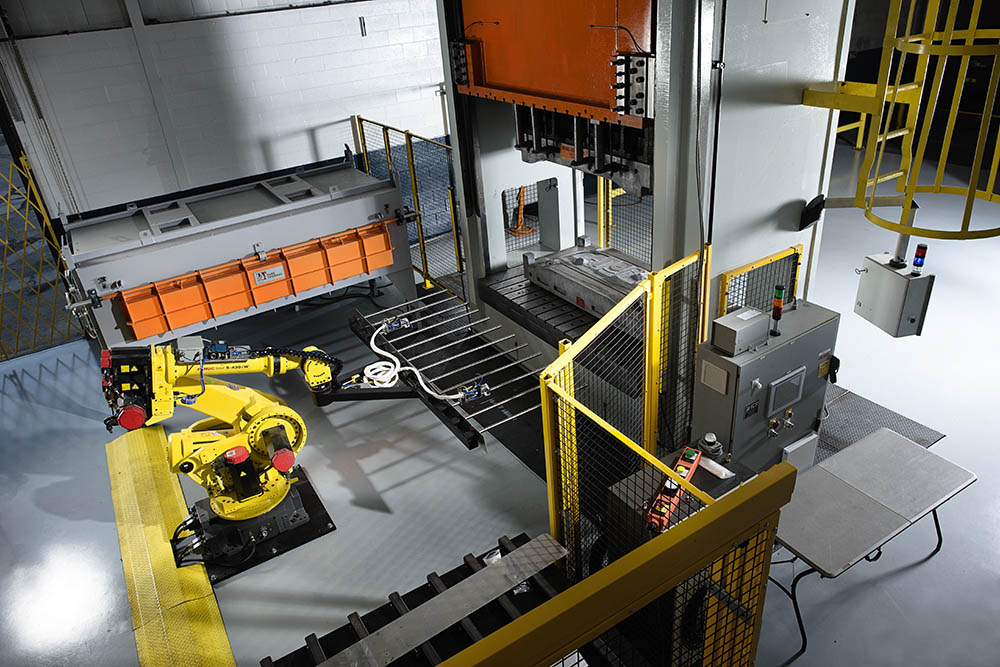

Hot stamping, also known as press hardened steel (PHS), is a process where a sheet of metal is heated in a furnace, transferred by a robot into a press, and formed in a steel or kirksite die. Our fully automated low volume, hot stamping cell provides reliability and repeatability in the manufacturing process of your parts. The onsite metallurgy lab allows us to test our hot stamped parts post-production in order to validate the material properties and ensure that we meet your expectations for high quality products.

Our state-of-the-art hot stamping cell and metallurgy lab allow us to provide our customers with quality products every time.